Nitrogen+Syngas 362 Nov-Dec 2019

7 August 2025

Problem No. 57: Higher moisture content in urea melt due to vacuum pressure issues

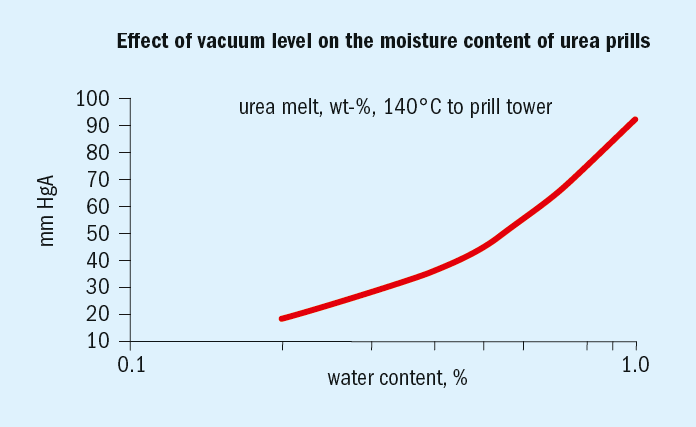

To illustrate the direct effect of vacuum level on the moisture content of urea prills please refer to the wt-% urea melt graph for aqueous urea at 140°C. As the absolute pressure increases (lower vacuum) the urea melt declines in concentration (water content % increases). With this illustrative graph, one can quickly see the effect of suction pressure on the moisture content of the urea melt. A non-optimum vacuum pressure is one cause of high moisture content in the urea melt, but there are also other possible causes as you will read in the round table discussion below. Sharing troubleshooting cases leads to a much wider view on the possible causes and helps to solve problems more quickly.

Mohammed Munir of Pakarab Fertilizer in Pakistan starts the Round Table discussion: We have a 300 t/d Snamprogetti urea plant (ammonia stripping process) on site. The vacuum system design has two vacuum separators: V-6 at 0.3 atm and V-7 at 0.03 atm. Recently, we experienced higher moisture content in the product due to V-6 and V-7 pressure fluctuations to 0.4 and 0.07 atm respectively. I am interested in the relationship between the variation of the pressure in V-6 and V-7 and the moisture content.

Muhammad Kashif Naseem of SAFCO in Saudi Arabia replies: The vacuum of the evaporators is dependent on the performance of the cooling system and the ejectors. There is a relationship between temperature and vacuum pressure which is directly proportional to the moisture. Please check if the vacuum condensers have urea polymers depositions. In that case flush the condensers and ejectors.

Ancaza of Igsas in Turkey shares his experience: Please also consider the following possible causes of a higher moisture content in the urea melt:

- Upstream of the separator a tube in the heat exchanger may be punctured (possibly due to vibrations and baffle hammering).

- A leak may be present in the steam jacket which forms part of the urea melt lines.

- The seal water of the urea melt feed pump may be leaking into the urea melt.

Prem Baboo of Dangote Fertilizers Projects in Nigeria contributes to the discussion: Please also refer to two other round table discussions “Vacuum problem in ACES TEC urea plant” and “Low vacuum pressure problem in final concentrator”, which contains interesting related information, like the following post from Al Cadena of Graham Corporation:

The ejector performance is a critical factor, meaning it creates a shockwave within the diffuser. This is where compression is created; the high velocity suction load/motive is converted into high pressure, designed to overcome the discharge pressure at the diffuser outlet. Decreasing the motive pressure to below the design pressure set by the manufacturer, will lead to the shockwave not establishing; thus, the ejector fails to operate.

As the capacity of the plant increases or decreases it will have an impact on the ejector’s suction pressure. The ejector operates on a curve, this performance curve is available from the ejector manufacturer. Lower load leads to a higher vacuum, and higher loads lead to a loss of vacuum.

The intercondenser removes condensable vapour and steam, thus reducing the load on downstream equipment. It also controls the discharge pressure of the upstream ejector. If there is fouling, higher cooling water temperatures are experienced and the heat transfer capabilities of the intercondenser will be diminished. The pressure within the intercondenser will increase, affecting the upstream ejector. If the discharge pressure is greater than what the ejector was designed for, it will disrupt operation of the upstream ejector.

Moisture droplets in steam lines are accelerated to high velocities, causing eroded nozzle internals. The diffuser inlet may also be damaged. Good practice would be to have a steam separator and trap installed before the ejector’s motive steam connection.

Mohammed replies: Thanks a lot, that helped! I am also interested in the relationship between the differential pressure of the two vacuum stages (V-6 and V-7) of the Snamprogetti

plant and the moisture content in the product. At the time of our incident, our V-6 operating pressure was 0.4 atm (design 0.3 atm) and V-7 was 0.05-0.07 atm (design 0.03 atm).

Prem responds: The vacuum conditions seem ok to me: 0.4 ata and 0.05 ata are not so bad. The design condition of the temperatures are also an important factor: At a design condition of 0.33 ata the temperature outlet is 128°C and at 0.03 ata the outlet temperature is 140°C.

If your vacuum condition is more than 0.3 ata, for example 0.4 ata, then the temperature must be higher than 128°C and also similar for the 2nd stage vacuum. However, I think your vacuum conditions are ok. The following problems may be occurring:

- water or steam ingress in urea solution;

- flushing water quantity not optimum at that time;

- separator flushing conditions;

- erratic pressure transmitter (1st and 2nd stage);

- sometimes flushing water goes towards the process side while its direction should be towards the condenser side. It can happen due to perforated coil disturbance (this is a shutdown job), in this case the flushing water must be closed;

- flushing water injection or low pressure steam injection condition.

Jim Lines of Graham Corporation in the United States shares his expertise: Increased operating pressure for both V-06 and V-07 is unusual. There are certain initial considerations.

- Is there solids build-up in the booster ejector of V-07 and precondenser of V-06 removed via daily flushing? Most plants have flushing nozzles in the booster ejector and precondenser that are operated once per shift or daily at a minimum for 10-15 minutes to reduce solids that build up. Solids formation will hinder booster ejector performance dramatically and will act as fouling in the precondenser, thus reducing its condensing efficiency.

- Is your plant operating well above nameplate capacity (although for V-07 it is appears that the booster is operating in a “broken” condition)?

- Is the steam generated by the high pressure carbamate condenser at a pressure below the minimum for proper ejector operation? The ejector performance curves will provide minimum steam pressure requirement for satisfactory ejector performance.

- When was the last maintenance inspection of ejector motive nozzles and internals? Is there corrosion or erosion damage of the ejectors resulting in poor operating capability?

| This series of discussions is compiled from a selection of round table topics discussed on the UreaKnowHow.com website. UreaKnowHow.com promotes the exchange of technical information to improve the performance and safety of urea plants. A wide range of round table discussions take place in the field of process design, operations, mechanical issues, maintenance, inspection, safety, environmental concerns, and product quality for urea, ammonia, nitric acid and other fertilizers. |