Fertilizer International 527 Jul-Aug 2025

7 July 2025

Tailored fertilizer blending – from inline coating to full plant solutions

HANDLING, BLENDING & STORAGE

Tailored fertilizer blending – from inline coating to full plant solutions

As the global demand for high-performance fertilizer blending systems continues to grow, Dutch manufacturer EMT remains a key player in delivering custom-engineered solutions. With over 35 years of experience and installations in more than 80 countries, EMT focuses on practical, modular systems that integrate seamlessly into diverse operational environments. Zico Zeeman, EMT’s Commercial Director, highlights two notable recent projects.

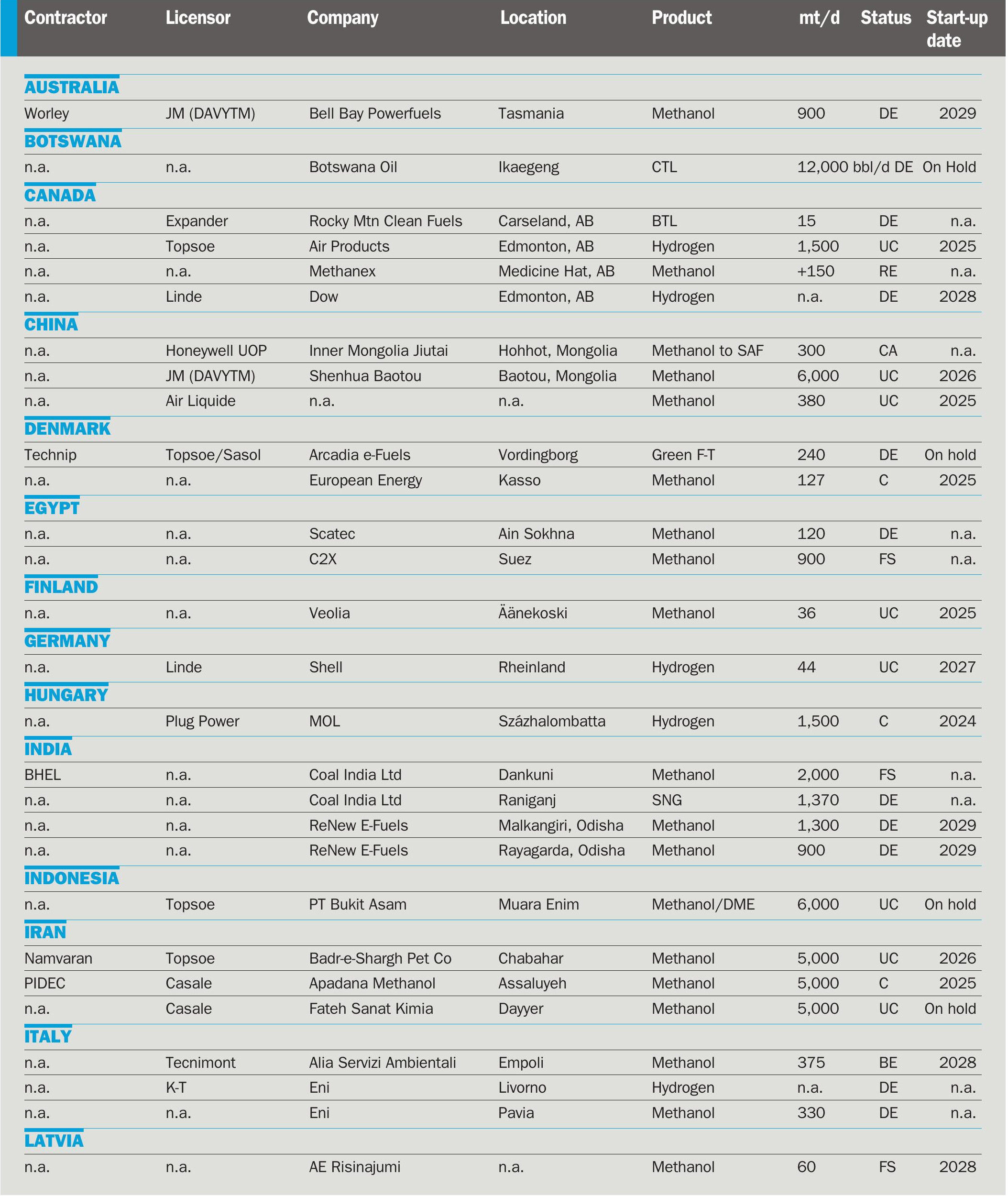

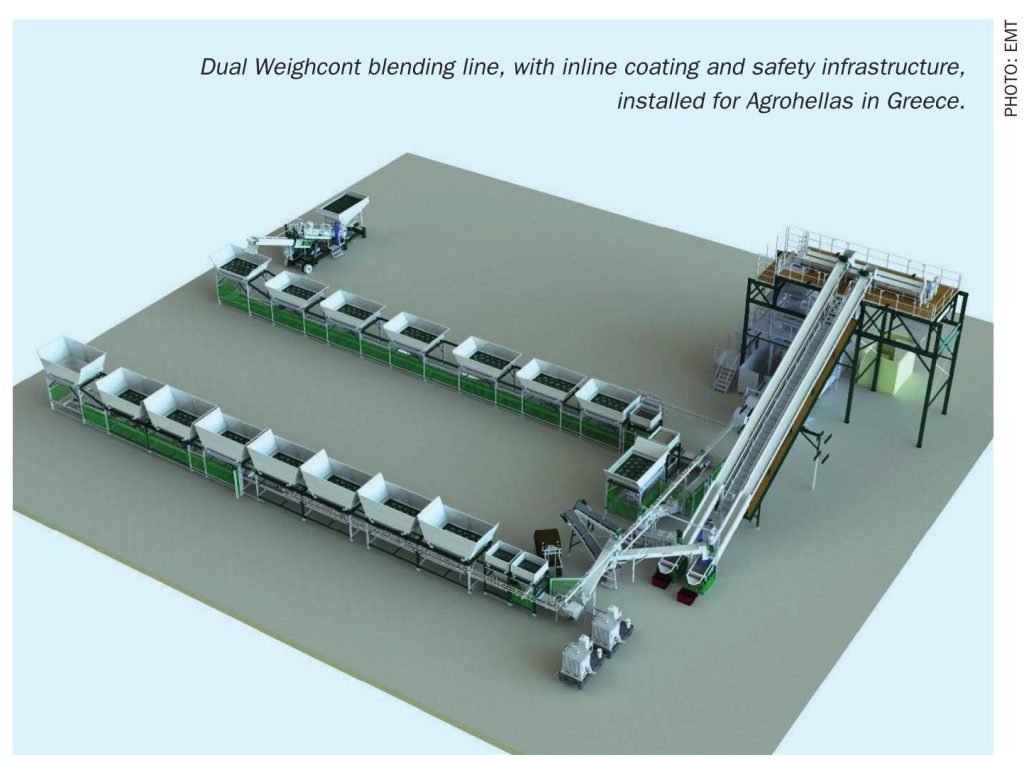

Dual-line continuous blending system for Agrohellas in Greece

For Greek fertilizer blender Agrohellas, EMT delivered one of its most comprehensive installations to date: two parallel Weighcont continuous blending lines, each equipped with 10 dosing hoppers, multiple liquid adding units, inclined blending screws and coarse screens.

To handle a wide range of raw materials, both lines were fitted with custom hopper configurations – including 9m³ and 12m³ extensions – and pre-cabled weighing units for fully automated dosing. Stainless steel support frames, access platforms, and conveyor safety features were integrated throughout the layout to meet both performance and operator safety requirements.

A key component of the line is EMT’s liquid coating unit, which includes a continuous weighing scale, pump, stainless steel piping or special hoses, and distribution system. This configuration allows Agrohellas to apply liquids in the blend with high dosing accuracy, without interrupting the blending process.

Following blending, material is screened using a 120 m³/h fertilizer vibrating screen before being transported to the bagging equipment. The complete plant is designed for reliable, high-capacity operation with central control and real-time feedback.

The installation of this ultramodern production line in Anchialos, Thessaloniki, represents a major investment in capacity by Agrohellas and demonstrates the company’s commitment to supplying the domestic agricultural market, now and into the future.

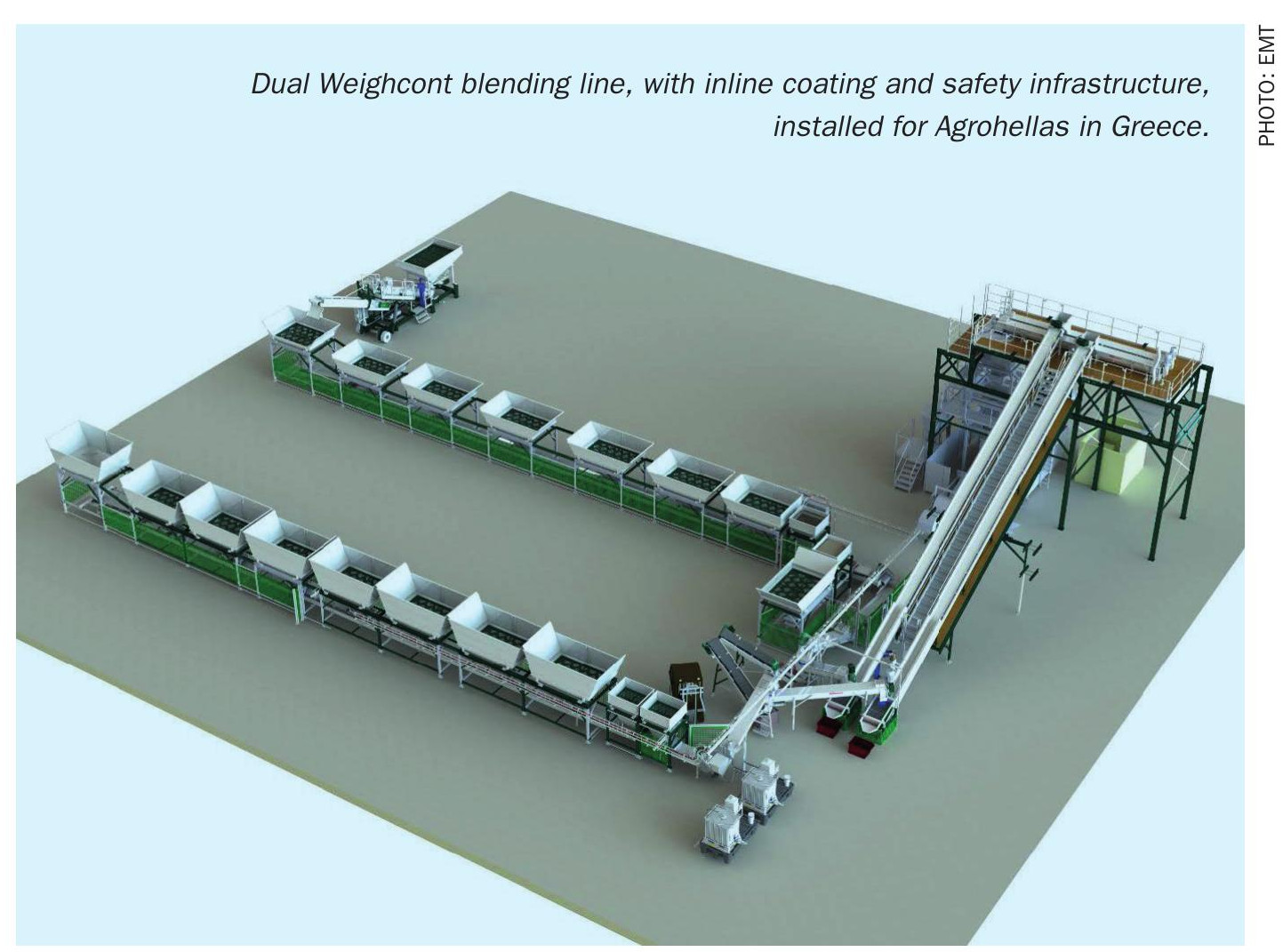

Inline coating and high-speed twin big bagging for Thomas Bell

In the UK, fertilizer distributor Thomas Bell partnered with EMT to design and fabricate a blender with a dedicated inline coating line for granular urea. This compact system applies liquid treatments directly into the material flow, using weigh-controlled dosing to ensure consistent coverage. After treatment, the urea is directly added to the blend.

To support the higher output from this blender process, EMT also supplied a Twin Big Bag High Speed filling unit, capable of filling two flexible intermediate bulk containers (FIBCs) simultaneously at rates up to 120 bags/hour. The system provides fast, clean, and automated handling – ensuring high throughput without sacrificing accuracy.

A special feature of this system is the twin elevator principle. To prevent incompatible products being transported in the same elevator, the customer has two elevators, both being able to fill either hopper of the twin bagging unit.

This equipment combination allows Thomas Bell to coat and bag efficiently within a limited footprint, delivering flexibility in product handling and seasonal product demands. Investment in the new system will help the company maintain its status as the UK’s largest privately-owned fertilizer importer offering a wide range of high-quality products – backed up by state-of-the-art blending plants, 150,000 sq ft of undercover storage and its own fleet of lorries.

Modular thinking, global results

Whether it’s a greenfield installation or a retrofit in an existing warehouse, EMT designs its systems with modular logic. From small and big bagging lines to batch blending, coating, and screening equipment, each part is built to match the customer’s process and raw materials.

With its in-house team of mechanical, electrical and software engineers, EMT continues to support producers worldwide with machines that combine reliability with flexibility. All systems are assembled and tested in the Netherlands, with international installation and remote service provided by the company’s own technicians.