North America

13 June 2025

Press Release: Northern Nutrients announces new ownership structure and plant expansion

Northern Nutrients’ Press Release: 12 June 2025,Saskatoon, Canada

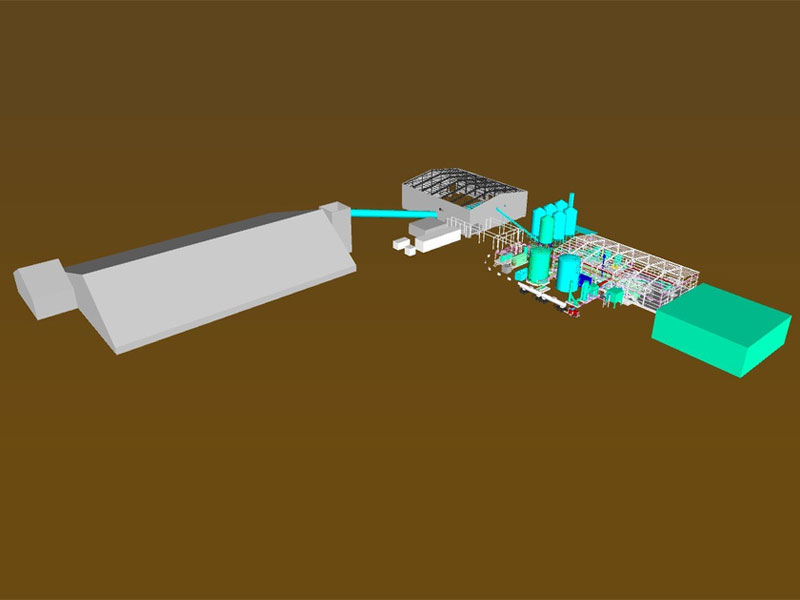

As part of this new strategic partnership, Shell Trading Canada has invested in expanding Northern Nutrients’ current facility, resulting in the formation of a new joint venture. The expansion will result in a tripling of current capacity of 50,000mt to 150,000mt annually of sulphur focused fertilizers.

Founded in 2016, Northern Nutrients has been at the forefront of bringing innovative solutions to the agriculture market for close to a decade. The company’s state-of-the-art facility near Saskatoon produces enhanced nitrogen sulphur fertilizers using the Shell Thiogro Technology. Their flagship product, Arctic S, boasts an impressive composition of 11% nitrogen and 75% micronized elemental sulphur.

The collaboration between Northern Nutrients and Shell underscores their shared dedication to providing retailers & farmers with high-quality, and efficient fertilizer solutions. The expansion of the Saskatoon facility is expected to boost production capacity and meet the growing demand for innovative fertilizer products. The project is expected to create close to 60 full time construction jobs, as well as numerous full time positions in ongoing operations.

“Since local production of Arctic S began in 2022, the market response across North America has exceeded our expectations making now the perfect time to expand our production capacity, and Shell the perfect partner to do it with.” says Ross Guenther, CEO & co-owner of Northern Nutrients.

Northern Nutrients Co-Owner Rob Owens adds “Bringing Shell Trading Canada on as a strategic joint venture partner makes sense on multiple levels to continue the momentum Northern Nutrients has built over the past few years.”