Reducing CO2 emissions with AdWinMethanol CC®

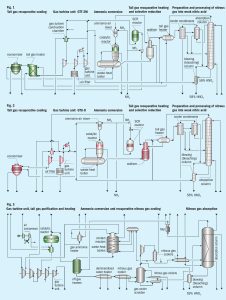

In a carbon-constrained world, carbon capture and utilisation or storage (CCUS) installed on a methanol plant is a necessary and feasible solution. The new, patented AdWinMethanol CC® technology, jointly developed by thyssenkrupp Industrial Solutions AG and GasConTec GmbH, integrates carbon capture into large-scale, natural gas-fuelled methanol production to yield a drastically reduced carbon footprint. U. Koss and W. Balthasar of GasConTec and J. Wagner of thyssenkrupp Industrial Solutions discuss how it removes CO 2 emissions in an efficient, cost effective, and environmentally friendly manner, taking advantage of the design features of AdWinMethanol ® .