Fertilizer International 529 Nov-Dec 2025

21 November 2025

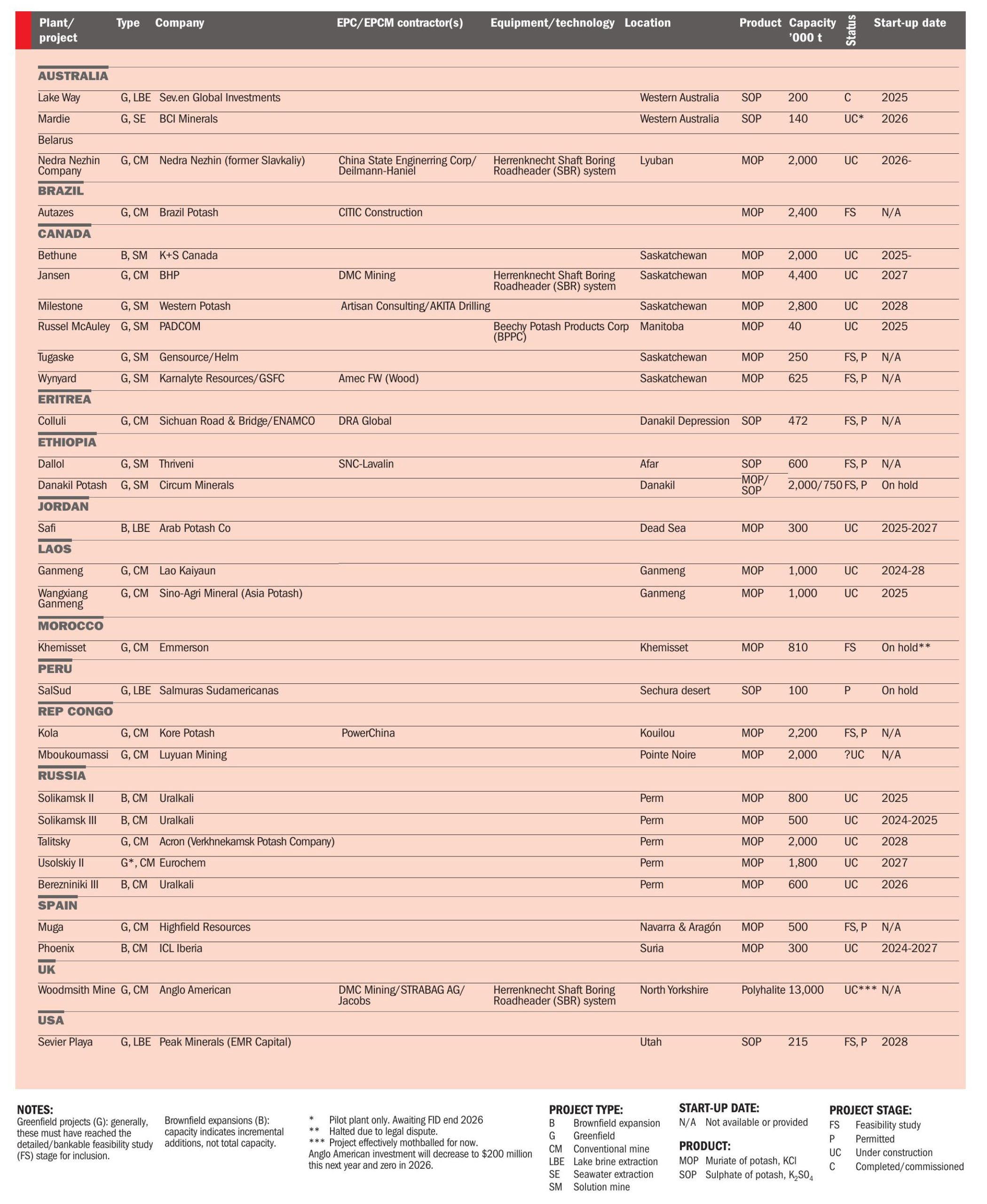

Potash project listing 2025

PROJECT LISTING

Potash project listing 2025

K+S Potash Canada marks the official start of a long-term investment programme to nearly double Bethune’s current potash production capacity to four million tonnes per annum.

Fertilizer International presents a global round-up of current potash projects.

EBNER

Fully-automated mobile evaporation & crystallization test plant

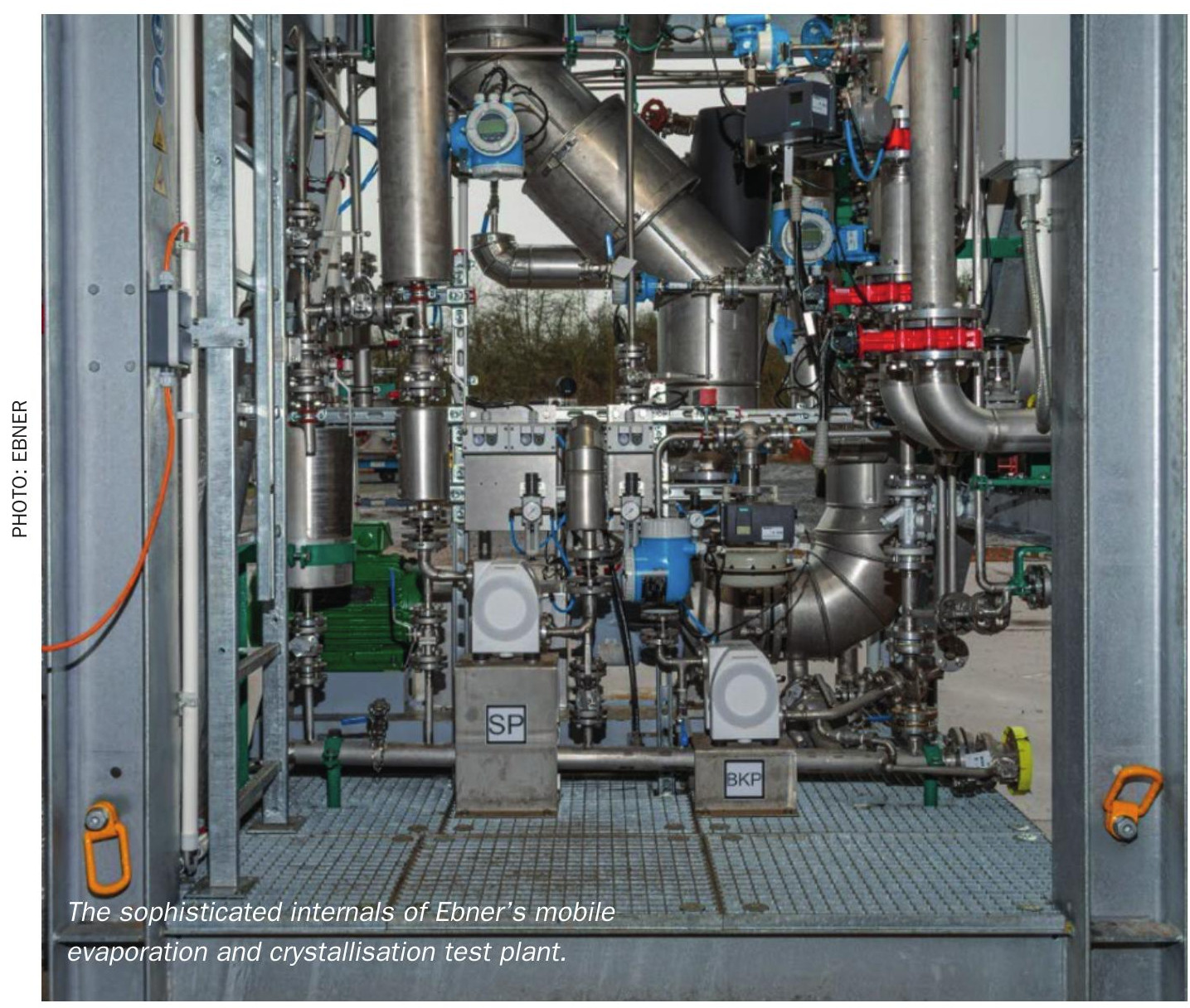

Germany’s Ebner GmbH & Co KG is a family-owned specialist designer and manufacturer of evaporation and crystallisation plants. The company develops tailor-made plants completely in-house, from the customer’s first enquiry to final delivery, having expertise that encompasses plant design, fabrication, erection, and start-up.

Ebner is an established global player. To date, the company has successfully constructed 600 new evaporation and crystallisation plants and optimised more than 200 other plants worldwide.

The company has extensive experience in the design and manufacture of evaporators and crystallisers for the potash industry. These are suitable for a range of potash salts, including potassium chloride (KCl) and potassium sulphate (K2SO4), widely known within the industry as MOP (muriate of potash) and SOP (sulphate of potash), respectively. The production plant capacities for these types of potash can vary from a few kg/h to more than 200,000 kg/h.

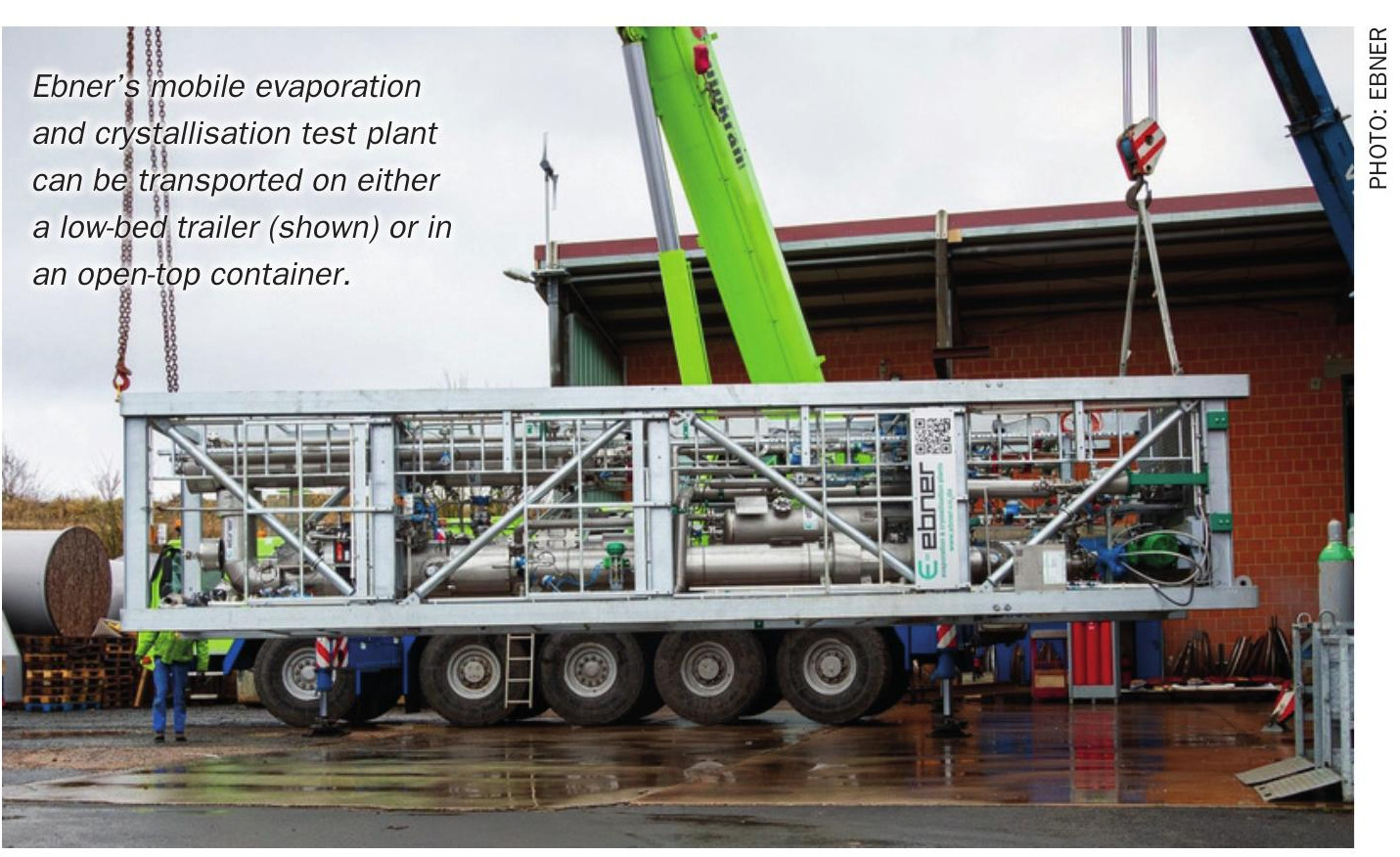

Ebner recently developed a mobile test plant that combines evaporation, cooling and crystallisation technologies in one compact unit. The plant, which has won an innovation award, is designed to cover all conventional evaporation and crystallisation processes.

Unique mobile test plant

The unit’s unique design and flexibility offers industrial users an opportunity to explore different process routes in a practical and cost-effective way. Being built into a steel frame, it can be transported easily on either a low-bed trailer or in an open-top container. Managing director, Stefan Ebner, explains the benefits:

“With this plant we provide something that does not exist anywhere else in the world. It is unique in its ability to cover a wide range of evaporation and crystallisation processes in one compact, mobile unit. For our customers, the benefit lies in the fact that the plant can be brought quickly to their site, enabling trials under real process conditions. Instead of investing in their own pilot system, they can rent this plant at low cost and test new process routes efficiently and safely. This approach allows them to save both time and money while accelerating the development of innovative technologies.”

Applications

The test plant can be operated in different modes depending on process requirements:

• Evaporation with/without crystallisation: up to 600 kg/h of water can be evaporated.

• Vacuum cooling with/without crystallisation: cooling capacities up to 200 kW are achievable.

• Direct cooling with/without crystallisation: also up to 200 kW, under vacuum or atmospheric conditions.

Advantages for potash producers

Potash producers will be among the main beneficiaries of this innovative mobile test plant. Granular potash production involves multiple crystallisation and concentration steps. New process concepts, therefore, often need to be verified before large-scale implementation. Traditionally, such trials are carried out in stationary pilot plants at remote locations. This requires transportation of feed samples and often leads to differences between laboratory conditions and real industrial environments.

The mobile concept developed by Ebner eliminates these drawbacks. By bringing the test plant directly to a production site, trials can be carried out with the actual raw materials used in day-to-day operations. This ensures more reliable results and minimises the risk of scale-up problems. Furthermore, customers can test variations in feed quality, process temperature, or cooling regimes without interrupting their own production.

The option to rent the plant is a key economic advantage. For companies evaluating new process routes, building and operating their own pilot unit often represents a major financial burden. In contrast, the Ebner test plant can be deployed at relatively short notice and at significantly lower cost. This reduces investment risk and allows companies to pursue innovative ideas that might otherwise remain untested.

Additional application areas

Although designed with the needs of the potash industry in mind, the test plant is equally well suited to other evaporation and crystallization tasks. Typical applications include:

- The concentration of process wastewater Recovery of salts from by-products

- Testing of new crystallisation strategies for specialty chemicals.

In each case, the modular and flexible design of the plant allows process engineers to adapt the operating mode to their specific requirements.

Practical aspects and transportability

The practical transport and handling of the unit is another advantage. Its compact footprint and transport dimensions enable relocation without significant logistical effort. Once on-site, the plant is quick to start up and easily connected to utilities. Its mobility also makes the plant suitable for multi-site operations, allowing any company to use it at a series of different production plants.

Conclusions

Ebner’s mobile test plant provides the industry with a novel tool for evaporation and crystallisation process development. Its compact design, flexibility and mobility, combined with the option of low-cost rental, make it a unique solution for potash producers and other industries seeking to explore new process technologies.

By enabling real-world trials under practical conditions, the plant helps customers reduce costs, shorten development times and minimise risks. In doing so, it sets a new benchmark for innovation in process engineering.

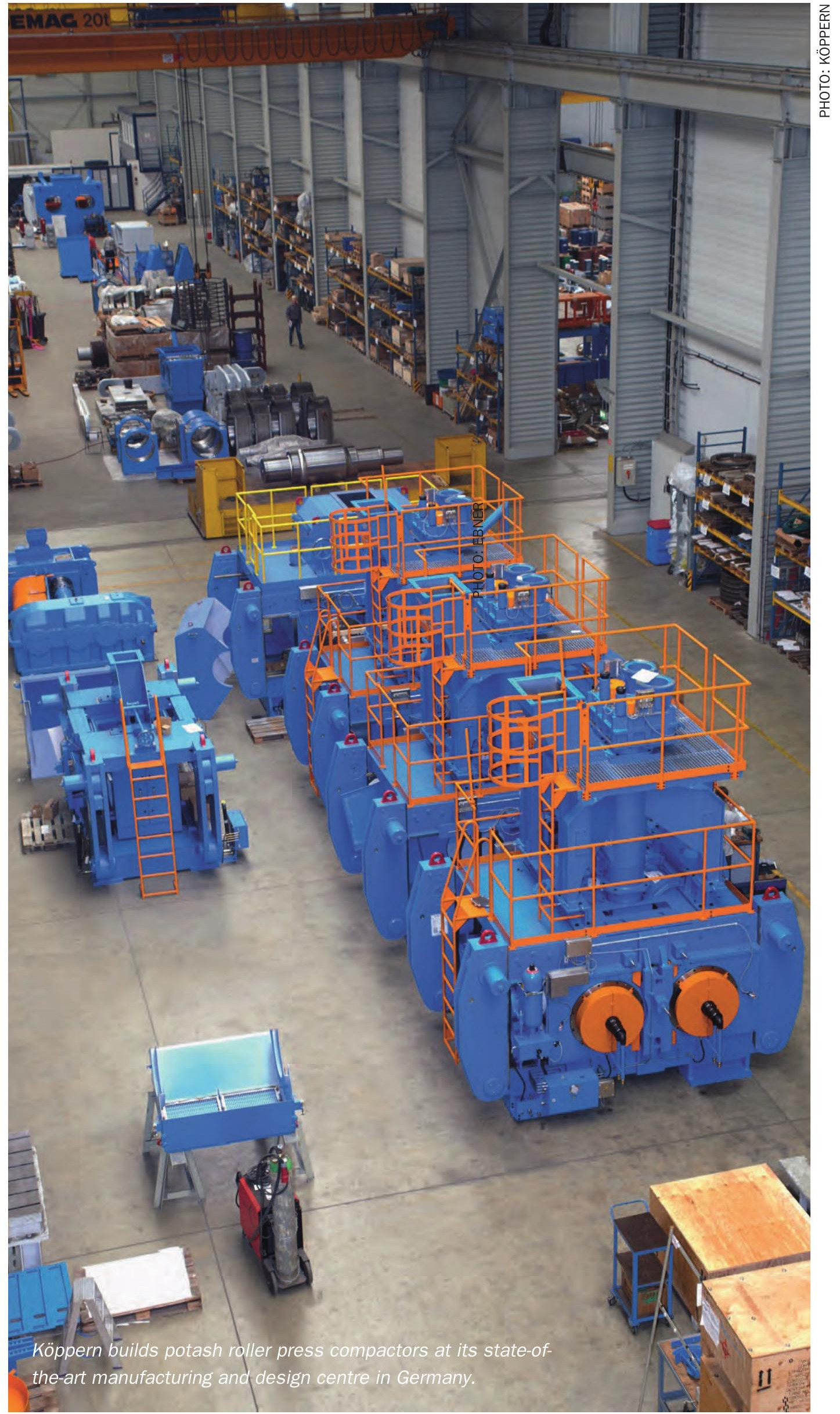

KÖPPERN

Successful potash sector sales in 2025

Köppern, a family-run business founded in Hattingen, Germany, has been manufacturing briquetting, compaction and comminution machinery since 1898. The company has been supplying compaction and granulation equipment and plants to the fertilizer industry for more than 70 years. Its sales include several hundred roller presses in over 60 countries.

Granular potash is produced almost exclusively by a compaction-granulation process. Fine-grained potash feed is generally compacted on roller presses to produce flakes with a density close to that (>95%) of natural potash. These flakes are then crushed and screened to produce a closely-sized (often 2-4 mm) granular product.

Three key components

A typical compaction-granulation plant for MOP (muriate of potash) consists of three key components – roller presses (compactors), crushers and screens – configured in closed-circuit. The feed is firstly compacted at an elevated temperature. Köppern typically installs compactors with a 1,150 mm diameter and 1,000 mm working width. Multiple compactors are often installed within one potash plant. These presses have a maximum flake throughput of approximately 140 t/h and a gross granular potash capacity of 40-50 t/h. After compaction, impact and roller mills, working in a closed-loop cycle with multi-deck screens, crush the flakes into granulate with an approximate density of 1.9-1.95 g/cm3 .

Since the 1990s, the preferred flake capacity of potash compactors has increased to 110-130 t/h. The majority of new compactor investments made by potash producers in recent years have been in designs of at least 100 t/h flake.

Design innovation

Köppern has introduced a number of innovations and design changes to ensure compactors of this size are safe, reliable to operate and deliver excellent flake quality. This has involved the modification of various subassemblies, including the frame, feeder, roll design, roll drive and the hydraulic systems.

Vibrations are a particular operational problem when de-aerating and compacting potash – as they can result in severe juddering that damages equipment. The risk of this can be reduced by lowering roll speed and/or feed rate. However, changing the compactor drive design to increase mechanical stiffness is a preferable way of solving this problem at source. This approach also maintains throughput, and is therefore less of a compromise for customers.

For many years, Köppern has stiffened the drive train of large roller presses by manufacturing these with planetary gear reducers mounted directly onto the roll shafts. The company delivered its first large potash compactor (130 t/h) with this drive technology to Germany in 1998. Since then, compactors with this drive design have been widely-adopted worldwide. For example, Köppern’s fertilizer compaction customers in Brazil, Canada, China, Croatia. Hungary, Jordan, Italy, Russia, Serbia and Spain have either modified or ordered new roller presses fitted with this type of main drive.

All large potash compactors supplied by Köppern since the early 1990s have also been supplied with a hinged frame. This allows quick access to rollers for assembly or maintenance. Rollers can be picked up easily without dismantling any part of the frame or feeder.

The feeder is an important component of the compactor. It needs to transport large volumes of material, de-aerate this effectively and distribute it evenly over the entire working width of the roller. The ability to independently adjust screw speeds also prevents misalignment by controlling the gap between rollers. Meeting these requirements prompted Köppern to develop a special double-screw feeder design. This design was first introduced into the potash industry in the mid-1990s in roller press upgrades in Germany and Belarus. The newly developed double-screw feeder was subsequently supplied to K+S in Germany and further clients around the world. In 2025, Köppern sold ten potash compactors: two to Canada, six to Congo and another two to a Central Asian state customer.

It is also economically advantageous to provide the roller body with exchangeable tyres, as this allows refurbishment of the tyre profile after wear.

Most of the above improvements and new design features, developed by Köppern over the years, can be found in many compactors used today by the global potash industry.