Fertilizer International 528 Sep-Oct 2025

13 September 2025

The value of fine screening

POTASH MINING & TECHNOLOGY TRENDS

The value of fine screening

In this article, Danny Luu, Processing Engineer, Derrick Corporation, outlines the transformative role of fine screening in potash and phosphate processing. Drawing from real-world case studies and technical insights, he highlights how fine screening has become a core component of modern mineral processing flowsheets.

Phosphate and potash ore are essential building blocks of the modern world, particularly in agriculture, where they form the basis of fertilizers critical for global food production.

As the demand for high-purity products grows and environmental regulations become more stringent, producers in the potash and phosphate industries face mounting pressure to improve efficiency, reduce costs, and minimise environmental impacts. Helping to meet these challenges is fine screening technology – a significant technological advance that, by providing a modern approach to particle classification and separation, offers compelling economic and operational benefits.

The need for mineral processing innovation

Traditional mineral processing methods, while effective in their time, often struggle to keep pace with the demands of today’s industry. Conventional equipment, such as Huck bolted screens and hydrocyclones, have long been used for particle size classification in both phosphate and potash plants. Yet, these technologies carry limitations, as discussed below.

In the context of rising energy prices, stricter environmental regulations, and the need for sustainable mining practices, these drawbacks are becoming increasingly unsustainable. Producers are therefore seeking new technologies that can deliver higher performance while reducing costs and environmental footprints.

Enter fine screening – a precise and innovative solution offering high classification efficiency, and therefore less physical misplacement of materials, compared to other classifiers. Greater efficiency, by reducing circulating loads, translates into less wear and lower energy costs. It also minimises overgrinding by precisely separating particles by size. This reduces the unnecessary grinding of already fine particles, preserving valuable minerals and improving recovery. Fine screening also consumes less energy overall, contributing to lower operational expenses. Lastly, it has a smaller footprint, as multi-deck configurations save valuable plant floor space.

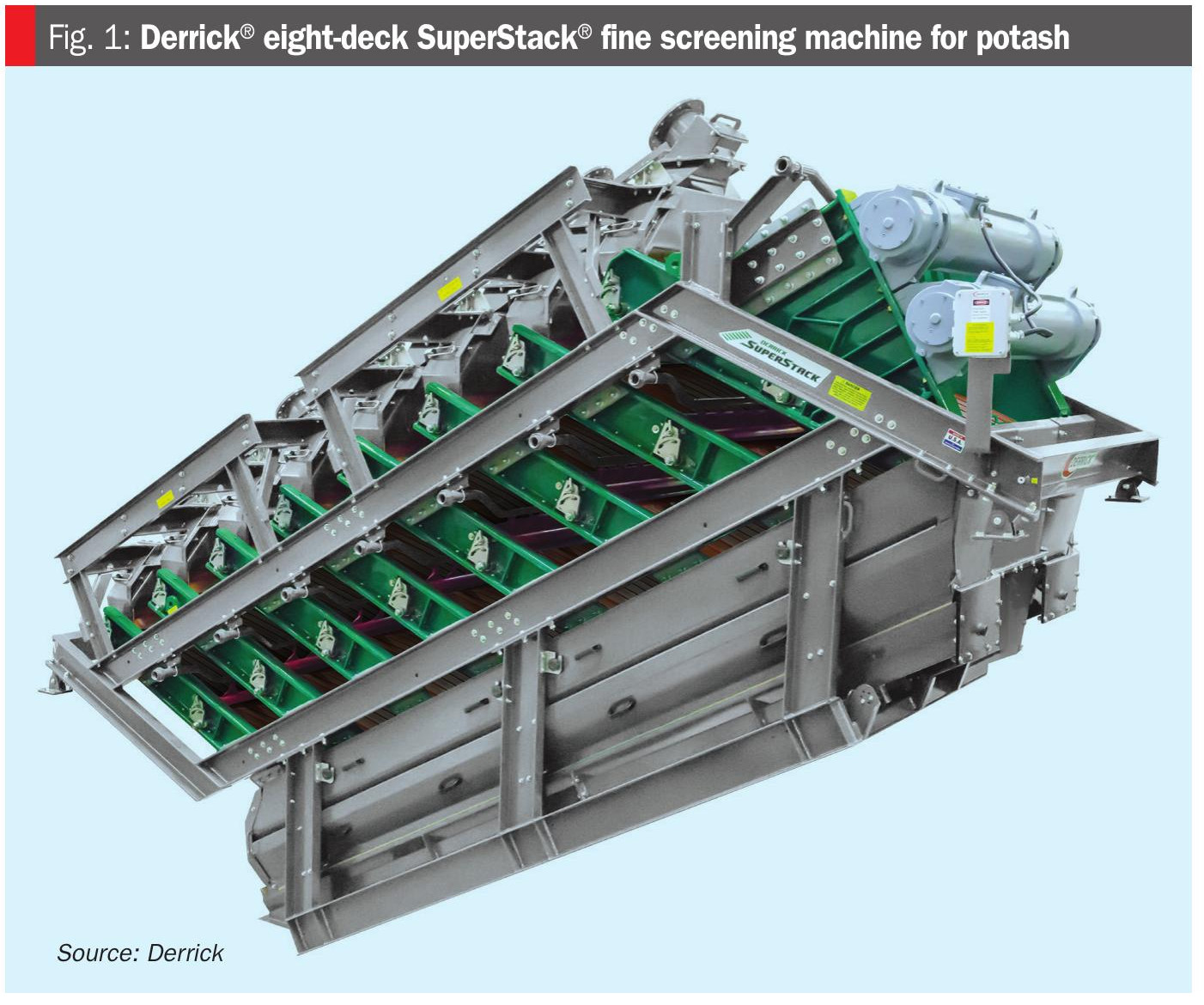

In summary, these attributes make fine screening an attractive upgrade in modern mineral processing operations. This is illustrated by the eight-deck SuperStack® machine offered by Derrick® Corporation shown in Figure 1.

Improving potash operations

Potash production faces challenges from past screening systems. Huck bolted screens, for example, often limit capacity due to their low open surface area, causing bottlenecks, and require significant space and structural support for their high dynamic loading. Problems such as blinding, high maintenance downtime, shorter machine lifespans, and – most importantly – lower efficiency ultimately leads to both lower revenue generation and increased costs.

Modern fine screens from Derrick, such as the SuperStack replace the huck bolted screen to deliver the following benefits:

• >95% size separation efficiency

• Higher open areas, leading to greater capacity and reduced fines generation

• Smaller footprint – often less than half that of huck bolted screens

• Lower dynamic loading, reducing structural steel requirements

• Quick panel changes – approximately 2-3 minutes per deck

• Longer machine lifespan – 8 to 10 years or more

• Long panel life of 2 to 4 years.

Potash applications

Primary sizing screens: usually positioned after the crushing and scrubbing stage, these screens cut at a 4.5 or 32 mm size range to send the coarse (de-brine) back to the crusher. Having a classifier that’s cutting efficiently is critical for avoiding sending fines back to the crusher, as this leads to overgrinding and recovery loss. Lower efficiency also reduces the overall tonnage capability of the circuit.

Deslime screens: remove slimes that hinder effective flotation separation of potash. This step comes after the grinding circuit and before flotation, with a hydrocyclone as the traditional classifier of choice in this application. Derrick screens can, however, classify more efficiently with this improving flotation recovery, as there is less misplacement of particles.

Regrind screens: these go into the process after the flotation stage to improve recovery by recapturing the coarse unliberated particles (usually plus 1mm) and sending these back to the crusher.

Case study: success in Saskatchewan

A compelling example comes from Saskatchewan, Canada, where more than 60 Derrick Stack Sizers operate across six potash plants. These installations handle screening at sizes such as 4.5 mm, 3.2 mm, and 1.4 mm.

The following benefits are reported by one of the world’s largest potash producers:

• Over 25% more open screen area compared to huck bolted screens

• Approximately 20% higher separation efficiency

• A 50% reduction in the amount of -70 micron particles, minimising fines

• An increase of around 2% in potash recovery – a substantial gain given the high value of the product

• Recirculating load reduced by 35%.

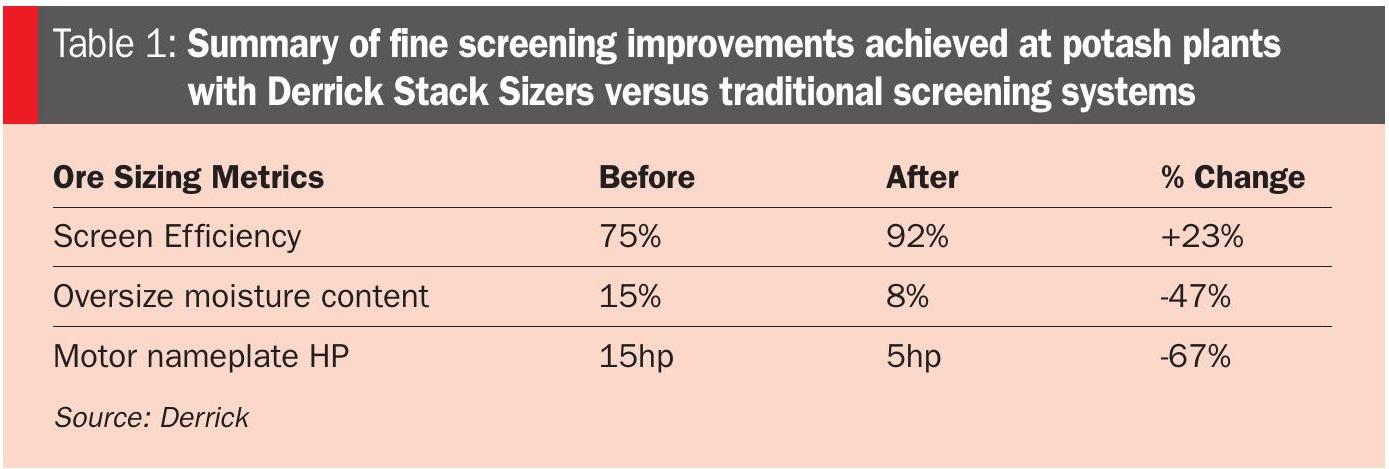

Additional benefits, as reported by Derrick’s customer, are summarised in Table 1.

Transforming phosphate processing

Traditionally, phosphate plants have relied on hydrocyclones, hydrosizers, and fluidised bed separators (FBS) for particle classification. However, these systems often suffer from significant drawbacks, including:

• Lower efficiency

• High circulating loads

• Excessive overgrinding, leading to lower recovery rates

• Increased power consumption and operating costs.

Fine screening, particularly using high-frequency vibrating screens, has the following benefits:

• Higher classification efficiency (85-95%)

• Significantly reduced circulating loads (100-150%)

• Less overgrinding improves overall recovery, preserving valuable phosphate particles for flotation

• Lower power and maintenance requirements.

Overall, these advantages translate into increased throughput, reduced costs, and improved sustainability.

Case study: a South African phosphate mine

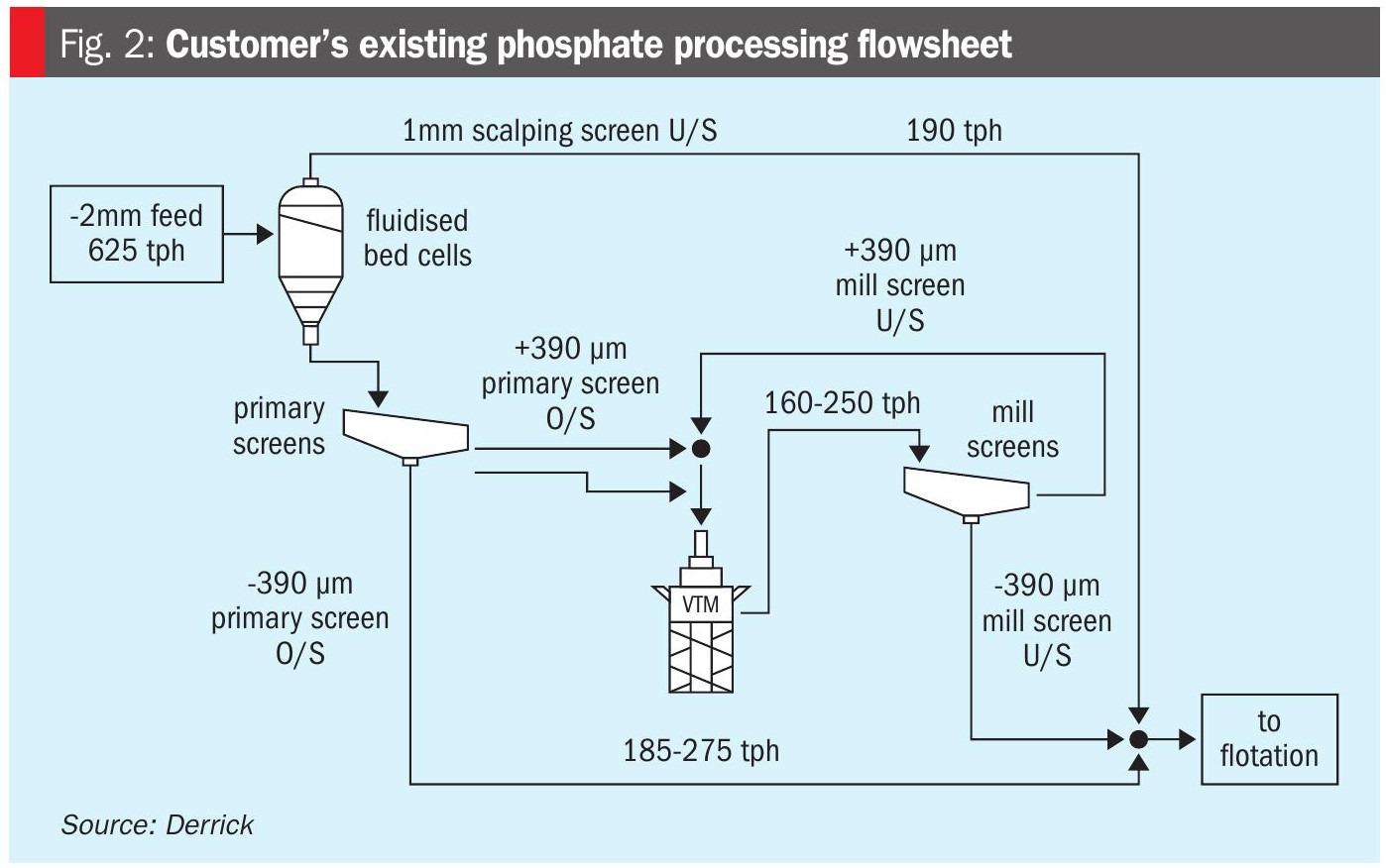

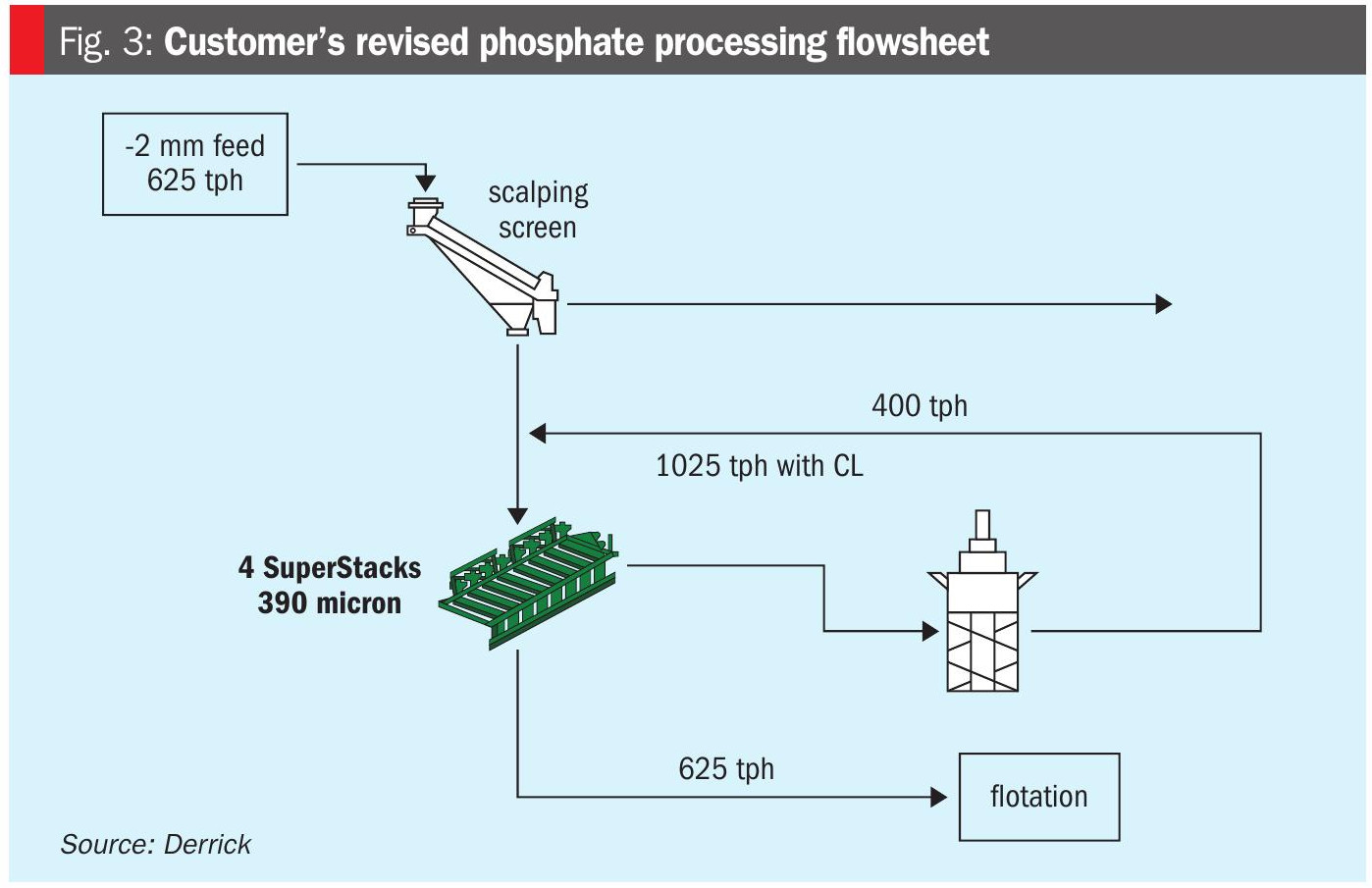

A phosphate mine on South Africa’s west coast illustrates the advantages of fine screening. Initially, the flowsheet consisted of a fluidised bed separator followed by a closed grinding circuit with two-stage screening before flotation (Figure 2).

Working with Derrick Corporation, the mine tested an alternative solution. Full-scale laboratory trials demonstrated ~90% classification efficiency using 350/390-micron screens with spray water. Ultimately, the recommended flowsheet was simplified to screening with four SuperStack screens in a closed mill circuit, replacing ten competitor screens, and the fluidised bed separator was replaced with a scalping screen, as shown in Figure 3.

This successful South African case study highlights how fine screening can modernise phosphate processing, delivering substantial economic and operational benefits.

From other installations, phosphate industry clients have reported the following benefits:

• Production rate increased by 30%

• Flotation reagent consumption decreased

• Power usage dropped by 20-25%

• Circulating load reduced from over 400% to 135%

• Panel life exceeded 7,000 hours

• Lower capital and operational expenditure due to fewer screens, a smaller footprint, and reduced maintenance needs.

Conclusion

Fine screening technologies such as Derrick’s SuperStack® have proven to be game changers in phosphate and potash processing. They deliver superior efficiency, lower operational costs, and significant sustainability advantages. As global demand for fertilizers grows and the industry faces stricter environmental standards, fine screening stands out as a key solution for mining operations looking to secure a profitable and sustainable future.

From Derrick’s perspective, the path forward for the mining industry is clear: to thrive in a changing world, embracing innovative solutions like fine screening is not just wise – it’s essential.

Acknowledgement

This article is based on a presentation given by Danny Luu at this year’s CRU Phosphates+Potash Expoconference, Orlando, Florida, in April. The call for papers for next year’s event in Paris, 13-15 April 2026, is now open: events.crugroup.com/phosphates/call-for-papers